Finishing Systems

Girbau Industrial finishing systems — feeders, ironers, folders and stackers — work in concert for unrivaled quality, efficiency and productivity. Backed by industry-leading warranties and offering superior programmability to meet a huge variety of needs, Girbau Industrial finishing systems are configured to meet each application’s unique productivity and quality goals.

Feeders

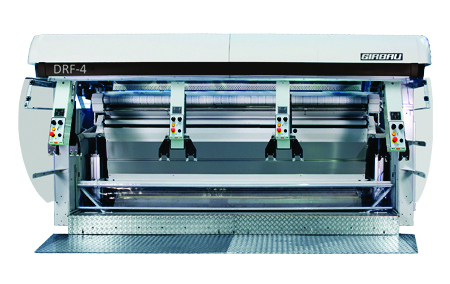

DRF Feeder

The DRF, Girbau Industrial’s most technologically advanced feeder, is quickly convertible to handle both large-, medium- and small-piece goods, making it highly desirable for high-volume laundries handling a variety of items. Offering unrivaled productivity, flexibility, programmability and quality, the DRF Spreader Feeder seamlessly and automatically straightens and feeds more than 1,200 large-sized items per hour into any height flatwork ironer. It accommodates one to four operators and one or two lanes simultaneously.

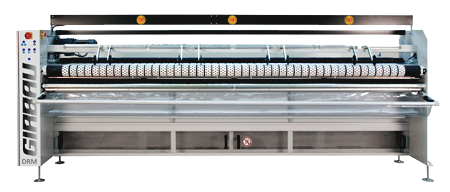

DRM+ Feeder

The DRM+ feeder, designed to save space without sacrificing production, is considerably smaller than other feeders on the market. This makes the DRM+ a sensible choice for operations with limited space and a need for high-volume finishing. The DRM+ quickly dresses, flattens and feeds wet items — napkins, tablecloths, sheets and pillowcases — into a corresponding ironer. The result is significantly improved productivity and quality over hand feeding.

DRBS Automatic Front Feeder

The DRBS automatically feeds linen of different types and sizes into a corresponding ironer. The DRBS Feeder allows for automatic feeding of large dimension items from two or three spreader-feeding stations, as well as manual feeding — with or without vacuum assistance — from one to four lanes. The DRBS — engineered for safety, durability, efficiency, productivity and flexibility — features spreading belts and a vacuum box and table to ensure quality automated feeding. When configured with an optional suction table and dual-transfer servers, the DRBS processes 790-1,000 items per hour from two or three stations. The design of the DRBS’s feeding clamps and technology make it possible to feed all types and sizes of linen.

Ironing Systems

PC-120

The most advanced flatwork ironer on the market, Girbau Industrial’s PC-120 — in natural gas, steam or thermal fluid heat — delivers superior performance, quality, durability and efficiency and features the advanced Inteli control with complete control over every ironing parameter. Available in 118-, 130- or 138-inch finishing widths with up to three, 48-inch diameter rolls, the PC-120 Chest Ironer processes up to 164-feet-of-linen-per-minute and is up to 93% efficient!

PC-80

The PC-80 Flatwork Ironer offers a highly flexible control, superior efficiency, high-speed ironing and solid durability. Engineered to catapult productivity at mid- to high-volume laundries, the PC-80 delivers exclusive features, rigid-chest technology and remote diagnostics. Available in natural gas and steam heat sources, the PC-80 produces superior results.

Compact+ 5-in-One

The Compact+ 5-in-One quickly feeds, irons, folds, stacks and accumulates an array of goods using up to four lanes. This space-saving system generates processing speeds of up to 82-feet-per-minute; is available in 24- and 32-inch diameters with 130-inch finishing width; and features natural gas or liquid propane (LP) heat sources.

Flatwork Folders

FRB

The FRB is a highly programmable folder offering one, two or four feeding lanes and the ability to automatically perform two to three primary folds and up to three cross folds. Ideal for the automated and high-quality folding of small and large items alike, including pillowcases, napkins, sheets and duvet covers, the FRB Flatwork Folder works with any model ironer or stacker. It’s backed by a 2-year IndustrialCare warranty. The FRB works with the APB Stacker to deliver quick, consistent stacks.

FR+

The FR+ delivers high-quality folding of large and small items using up to four feeding lanes. Highly programmable, it offers a touch-screen control and graphic menus for ease of use. It delivers two or three cross folds on one lane, or one or two cross folds on two lanes. Options include sliding table, ionized air + antistatic bar, small-piece tray and counter, small-piece accumulator, and more. Backed by a 2-year IndustrialCare warranty. The FR+ works seamlessly with the AP+ Flap Stacker for high-quality item stacking with compression technology.

Drywork Folders

FT-Lite

The FT-Lite quickly and accurately folds small- and large-scale items (47.2 x 94.48 inches) alike. Operators manually feed items onto a feeding table for rapid and accurate folding. The FT-Lite offers superb flexibility and is programmable to create primary and secondary folds. It automatically classifies and stacks items according to their dimensions.

FT-Maxi

The FT-Maxi automatically sorts, folds and stacks a variety of dry goods, delivering unmatched folding quality in less time. The FT-Maxi eliminates dry good pre-sorting for superior productivity and can sort, fold and stack up to four differently sized items — up to 47.2 x 92.5 inches — simultaneously.